Timings: Monday - Saturday: 9 a.m. - 6 p.m. Sunday: Closed.

Address: Korangi Creek Industrial Park, GA 60 - A7, Karachi City, Sindh 74900

Industrial Engineering

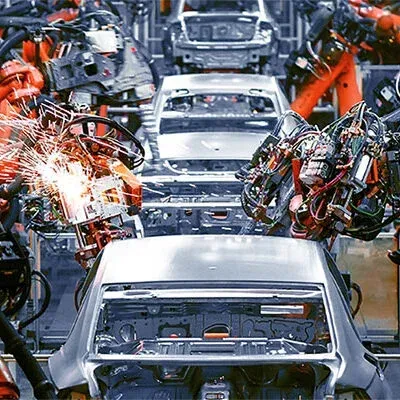

The modern era of the Auto Industry in Pakistan started developing in 1980’ s, when Suzuki Japan entered into a Technical License Agreement for assembly of a few models of cars and mini pickup trucks. Other Japanese assemblers like Toyota, Honda, Hino, Isuzu, & Nissan soon followed thereafter. After the year 2000, original equipment manufacturers (OEMs) from other countries like Malaysia, China, Korea, France, Sweden also entered the Pakistani market. Today Pakistan is the producer of large variety of two & three wheelers, cars, SUV’ s, commercial Vehicles, tractors, buses & trucks from multiple partner countries like Japan, Korea, Chinese, Malaysia.

A Rich Pool of Technical & Engineering Manpower

With the advancement in the auto industry over the years, Pakistan has also developed a large pool of technical, engineering & marketing professionals. In addition to setting up and running plants in Pakistan, these engineers also have extensive global experience in setting up and running automotive plants in countries like Bangladesh, Vietnam, Nigeria, Egypt etc, and working with Principals countries like Korea, China, Thailand, Japan & some European countries.With continued support from the Principals, Pakistani engineers are fully capable of successfully handling all facets of automobile assembly projects, right from the preparation of feasibility reports up to plant setup and installation, while remaining in compliance with budgetary constraints and time schedules. Pakistani Engineers are well versed in

Drafting, negotiating, and finalizing Technical License Agreements / MOU’ s.

Securing regulatory approvals;

Negotiation with potential part vendors, dealer networks;

Understanding and adopting global standards in the production processes such as in welding, painting, assembly line, quality audits, pre-delivery audits and after sales service as well as in plant engineering and local parts development;

Implementation of Production Processes & Schedules;

Establishing Key Performance Indicators (KPIs) and ensuring their implementation and monitoring;

Promoting and assisting in localization of spare parts manufacturing industry;

Meeting all HSE guidelines and hiring of a competent team for smooth plant operation; and

Incorporating and implementing continuous productivity improvement tools such as Kaizen, TPS, 5S, JIT, QC Circles, ESS, OSHA Standards, ISO Standards 9000, 14000, 18000, 45001, Six Sigma, ILO Score Program etc.

To summarize, Pakistani engineers, Pakistani engineers can help in successfully setting up and running Greenfield automotive assembly plants all over the world in line with best international practices.

Our Association with the Automotive Industry

Our association with the auto industry started in 1980s as a supplier of paints, sealers & adhesives, manual & robotic paint spray and pumps for sealer application. With a rich experience of more than 43 years, we have extensive and in-depth knowledge and training in our field. We work in collaboration with our Principal partners in China, Malaysia, Thailand and France.

Since 2016-17, we have also been involved in setting up of Paint & Assembly Lines for various OEMs and Tier-1 Part Suppliers with support from, our Principal partners from China. Over the years we have developed a strong bond with Engineering and technical teams that have extensive experience of more than 40-45 years in automobile assembly plants. Our activities include, but not limited to, providing consultation for set up of assembly plants for the following classes of vehicles;

Buses

Heavy Duty Trucks

Commercial Vehicles

Cars & SUV’ s

Two Wheelers

Three Wheelers

Brand / Partner selection for assembly of cars, vans, commercial vehicles, heavy duty trucks, buses, special purpose vehicles, & two – three Wheelers.

Market research

Product selection

Arranging TLA / MOU / JV, technical collaboration, technology transfer etc.

Preparing technical & commercial feasibility reports

Plant Set Up

Team and man power selection

Trial and commercial production

Quality management

Organization setup including production, management, quality assurance, dealership network, marketing and sales promotion, and after sales service.

Technical trainings, meetings, & Seminars.

Weld shop

Weld Bond Adhesive

Hem flange adhesive

Mastic adhesive

Pumpable sheet metal stiffener (PSS)

Pumpable sound deadener (PSD)

Spot sealer

Paint Shop

Body sealer

Under body coating

Strong cavity filler

Acoustic cavity filler

Assembly shop

Direct glazing adhesive

Heat curing elastic adhesive

Interior adhesive

Our Pride

The first ever Bus was produced in 2008 in Pakistan using Bonding Adhesives. Today the technology introduced by Unico is a mainstay in the Bus Assembly all over Pakistan. This changed the buses assembled in Pakistan.

We pride ourselves on creating innovative products to serve the specialized needs of our consumers. We have Principal technology partners spread all over the world.

Location

Korangi Creek Industrial Park، GA 60 - A7, Karachi City, Sindh 74900

Contact us

0213 506 2726-7

0213 506 4322

Built by Exter Marketing | Powered by Exterly.io